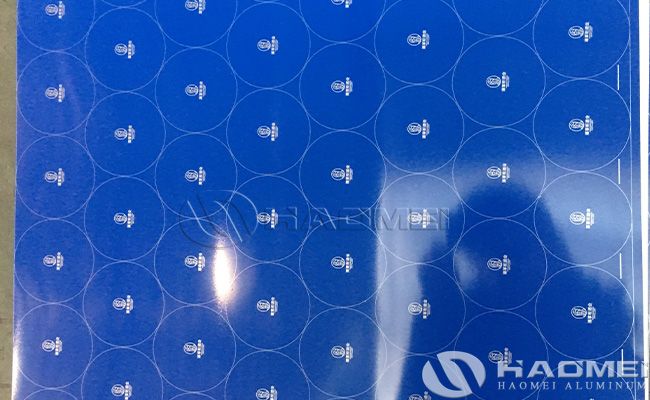

Chromized and Dos Treated Aluminium Sheet

Chromized and dos treated aluminium sheet

acquires a range of superior properties and characteristics that make

the treated stock more suitable for bottle cap production and

applications.

Chromized and dos treated aluminium sheet offer a number of unique advantages.

First

of all, chroming treatment can form a uniform and dense chromium oxide

layer on the surface of the aluminium sheet. This chromium oxide layer

not only effectively prevents the erosion of the aluminum sheet by rain,

chemicals and other environmental factors, but also improves the

corrosion resistance of the aluminum sheet in corrosive media such as

liquor and beverages, which greatly extends the service life of the

aluminum sheet. At the same time, because the formation of chromium

oxide film is carried out through physical and chemical oxidation

reaction, its coverage of the surface of the aluminum sheet uniformity

is good, without special mechanical and chemical treatment. In addition,

the chroming treatment significantly improves the hardness and abrasion

resistance of the aluminum sheet for bottle caps, enhances its impact

resistance, and further enhances the performance of the aluminum sheet.

In addition, the chromated film improves the abrasion resistance of the

cap stock, reducing wear and tear during transportation, storage and

use.

Secondly, with DOS treatment of aluminium sheet for bottle caps

is aluminum substrate through pre-treatment cleaning, chemical layer

and then coated with a layer of DOS oil, (DOS oil is the abbreviation of

dioctyl sebacate), DOS treatment of the main role is to prevent

oxidation and scratches, DOS oil treatment of the substrate is coated

with DOS oil on both sides, the general amount of DOS treatment for the

10-80mg% 2Fm2, which can isolate the aluminum sheet from the air, thus

preventing it from rusting and further improving the rustproof ability

of the aluminum sheet. At the same time, DOS oil treatment also helps to

improve the abrasion resistance and corrosion resistance of the

aluminum sheet, so that it can still maintain good performance in

complex environments. After DOS oil treatment of the substrate for the

next process manufacturers and then slit into sheets and strips and then

coated and printed into different specifications to facilitate the

subsequent processing of the pre-coated aluminium sheet substrate for

the use of the caps factory, DOS oil pre-coated aluminum coil due to the

more flexible subsequent processing, the use of a considerable amount.

Combining

the effects of chroming treatment and DOS oil treatment, this aluminium

sheet for bottle caps not only has excellent corrosion resistance, but

also good wear resistance and hardness, which can meet the needs of

bottle caps and other components used in complex environments. In

addition, this treatment also helps to improve the surface quality of

the aluminum sheet, making it more beautiful and durable.

Overall, the chromized and dos treated aluminium sheet has excellent performance performance, which is ideal for making bottle caps and other parts.

This resource is from https://www.aluminium-for-closure-caps.com/a/chromized-and-dos-treated-aluminium-sheet.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

评论

发表评论