Aluminium 6082 T6

Aluminium 6082 t6

alloy is a high-strength aluminum alloy with excellent physical and

chemical properties and is widely used in many applications. The

following is a detailed introduction of its alloy composition,

specifications, physical properties, chemical properties and

applications:

Alloy composition and specifications:

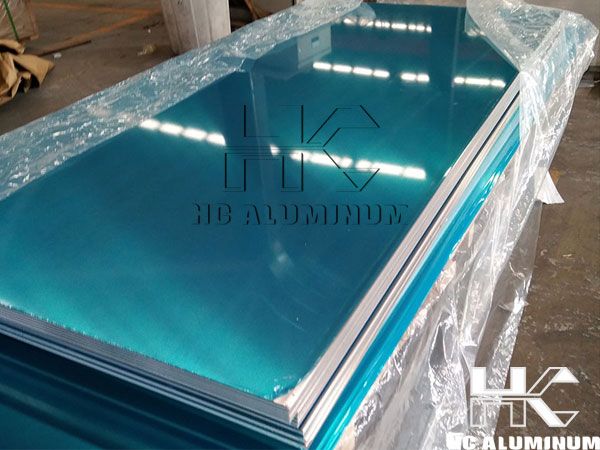

Aluminium 6082 t6 is mainly composed of aluminum (Al), magnesium (Mg), silicon (Si) and manganese (Mn). Among them, aluminum is the main component, accounting for more than 90%; the content of magnesium and silicon are between 0.6%~1.2% and 0.7%~1.3% respectively; the content of manganese is less than 0.5%. It also contains small amounts of trace elements such as copper (Cu), chromium (Cr) and zinc (Zn). In terms of specifications, 6082 t6 aluminium alloy is usually supplied in the form of sheets, rods, tubes, etc., and specific specifications can be customized according to customer needs.

Physical Properties:

Density: 6082 T6 aluminum alloy has a density of about 2.71g/cm³, which makes it lighter compared to ordinary steel, and helps to reduce structural loads and improve transportation efficiency.

Melting point: Its melting point is about 582~652℃, with good high temperature stability.

Coefficient of thermal expansion: The coefficient of thermal expansion is 23.2×10^-6/K, showing good thermal stability.

Hardness: In T6 condition, the hardness of 6082 t6 aluminum sheet can reach 95HB, showing high hardness and strength. According to GB/T 5237.1-2008 standard, its base hardness (HV0.1) should be ≥95 and coating hardness (HV0.1) should be ≥200.

Tensile coefficient: Regarding the tensile coefficient of 6082 T6 aluminum alloy, the specific value may vary due to material treatment, test conditions and other factors. In general, the alloy has high tensile and yield strengths, as well as good elongation, properties that enable it to meet the needs of a variety of complex structures.

Chemical properties:

Aluminum 6082 T6 alloy has good corrosion resistance, which is mainly attributed to the elements of magnesium, silicon, manganese and chromium in its alloy composition. The presence of these elements improves the alloy's corrosion resistance and allows it to maintain good stability in a variety of environments.

Applications:

Aluminum alloy 6082 T6 is used in a wide range of applications due to its excellent properties. In the construction field, it is commonly used to make profiles and tubes for building structures and decoration. In addition, it is widely used in the manufacture of vehicles, pedestals, furniture, lifts and fences. Due to its good machinability, weldability, extrudability and plating, 6082 T6 aluminum alloy is also often used to make various parts and components.

In summary, aluminium 6082 T6 alloy has a unique alloy composition, specifications and excellent physical and chemical properties and hardness, making it widely used in various fields. For more detailed information, it is recommended to consult relevant professional materials or consult experts in the field of aluminum alloys.

评论

发表评论