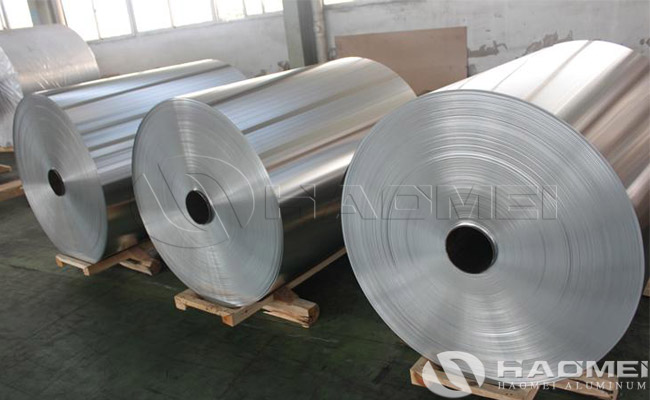

Aluminum Foil Paper Manufacturer

Haomei is a trustworthy aluminum foil paper manufacturer in China, we supply 0.006-0.05mm aluminium foil with alloy of 1060, 3003 and 8011. With rich experience on aluminum foil papaer product manufacturing, Haomei aluminum have advanced production line to process high quality product, we can supply ultra-thin aluminum foil with prime quality and factory price.

The production process of aluminum foil paper manufacturer Haomei are:

One step, smelting: use a large-capacity regenerative smelting furnace to convert the primary aluminum into molten aluminum, and enter the casting and rolling mill through the launder. During the flow of the molten aluminum, the refiner Al-Ti-B is added online to form continuous and uniform refinement Effect: The graphite rotor degass and removes slag online at 730-735℃, forming a continuous and uniform removal effect;

The second step, rough rolling: the molten aluminum after the first step is introduced into the casting mill for casting and rolling into billets; in this process, the cooling water inlet temperature in the inner cavity of the roll is controlled at 20-23°C, and the outlet water temperature is controlled at 28-32℃, the static pressure of the aluminum melt between the roll gaps is controlled at 0.004-0.005Mpa to ensure that the crystalline direction of the material is {100} area ratio> 95%, and the grain size is ≤ 5μm, and slabs of 6.5-7.5mm are rolled;

The third step, intermediate rolling: the above-mentioned slab is rolled again with a cold rolling mill, and when the thickness reaches 4.5mm, it is sent into the annealing furnace, heated to 360°C for 2 hours, and then heated to 580°C , hold for 18 hours, conduct homogenization annealing to make the grain size uniform and the directionality consistent; then continue to cold-roll in the cold rolling mill to 0.60mm, send it to the annealing furnace again, and heat to 460°C for 5 hours After that, the temperature is lowered to 400°C, the temperature is kept for 7 hours, and the intermediate annealing is carried out; then, it continues to be rolled into a thickness of 0.3mm as aluminum foil wool;

The fourth step, foil rolling: use a four-roll irreversible foil rolling mill to roll the above 0.3mm aluminum foil wool into finished aluminum foil. The production process of aluminum foil paper manufacturer is short, the operating cost is low, and the production investment scale is small. The quality of the produced ultra-thin aluminum foil can reach the most advanced level in the world. Compared with the production process of the hot rolling method, the investment cost is reduced in the production of billets in two-thirds, operating costs reduced by more than half.

For Price Plz Contact Whatsapp/Wechat: 0086 181 3788 9531

Or Email to nydia@aluminium24.eu

评论

发表评论