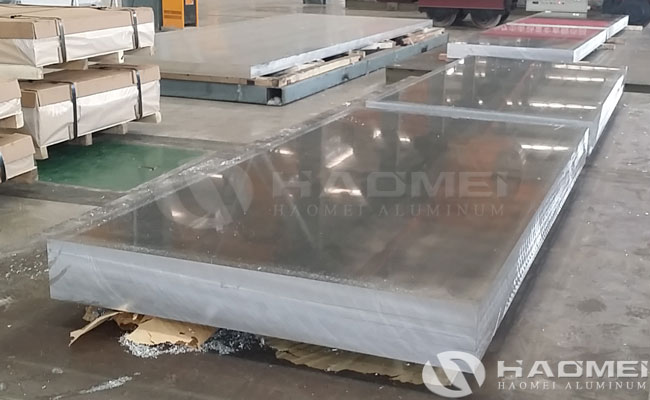

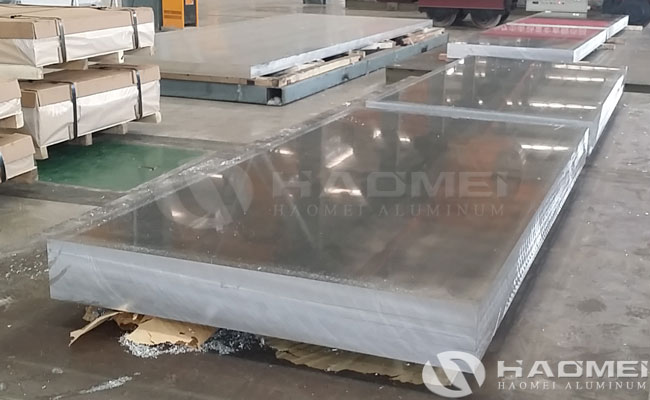

Factors that affect aluminum metal sheets quality

As a building material, aluminum metal sheets should have high quality, or the quality of construction projects cannot be guaranteed. In the aluminum sheet metal industry, the quality of aluminum sheet raw material not only affects the decorative effect, but also affects its practicality. So, what are the factors that affect the quality of aluminum sheet?

For Price Plz Contact Whatsapp/Wechat: 0086 181 3788 9531

Or Email to nydia@aluminium24.eu

- Cut corners

- Mixed raw materials

- Strict supervision

- The measurement is not timely

- Falsification

For Price Plz Contact Whatsapp/Wechat: 0086 181 3788 9531

Or Email to nydia@aluminium24.eu

评论

发表评论