What are the common quality defects of aluminum coil

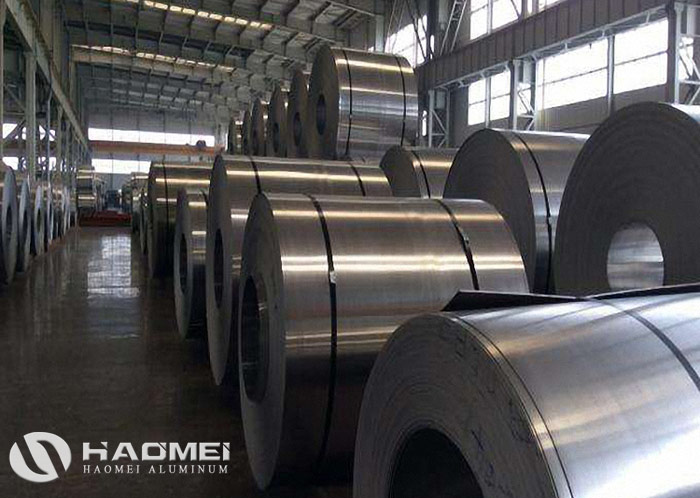

Aluminum coil is a metal production rolling by rolling machine, drag

the corner, and cut by flying shears. Aluminum coil are widely used in

electronics, packaging, construction, machinery, but in the manufacture

of aluminum coil

there will be some quality defects inevitably, so, what are the common

quality defects of aluminum coil? Here we will explain them to you one

by one.

1, the compound layer falls off: composite clad aluminum layer leave matrix falls off and form of the irregular defect.

2, embossing: due to strip crease, broken strip,roller surface irregular color difference periodically printed to the strip surface in the process of rolling.

3, waves, plate, strip various uneven phenomenon due to the non-uniform deformation of the floorboard, waves in the band edge of plate and strip are called edge waves, waves in the middle are called the middle waves, waves neither in the middle or edge are called the second rib waves, small size and assumes the circular waves usually referred to as breaker.

4, warped edge, after rolling or shearing strip edge cocked up.

5, lateral bending, longitudinal side of aluminum sheet and strip presents bending to one side of the flat state.

6, flat roll: roll core serious deformation, roll shape is not round.

7, wrong layer: strip face irregular rupture between layer s cause the surface is not smooth.

8, tower shape: coils move up to one side between layer and layer formed tower deviation.

9, loose roll: when the coiling and uncoiling ,loose between layer and layer, it can spread to the whole roll if it is serious.

10, bird's nest: at the end surface of aluminum coil has local "V" type defect.

Because of so many defects of non qualified aluminum coil product,people has to pay more attention to selecting, if you want a supplier who do not have all these problems, Haomei is your best choice, for we have strict inspect on the quality and producing process,all these problems can be avoid before the aluminum coils are produced. We can promise that all the product from our factory are all with international standard.

Reprinted from: https://www.aluminium-hm.com/new/aluminum-coil-quality.html

1, the compound layer falls off: composite clad aluminum layer leave matrix falls off and form of the irregular defect.

2, embossing: due to strip crease, broken strip,roller surface irregular color difference periodically printed to the strip surface in the process of rolling.

3, waves, plate, strip various uneven phenomenon due to the non-uniform deformation of the floorboard, waves in the band edge of plate and strip are called edge waves, waves in the middle are called the middle waves, waves neither in the middle or edge are called the second rib waves, small size and assumes the circular waves usually referred to as breaker.

4, warped edge, after rolling or shearing strip edge cocked up.

5, lateral bending, longitudinal side of aluminum sheet and strip presents bending to one side of the flat state.

6, flat roll: roll core serious deformation, roll shape is not round.

7, wrong layer: strip face irregular rupture between layer s cause the surface is not smooth.

8, tower shape: coils move up to one side between layer and layer formed tower deviation.

9, loose roll: when the coiling and uncoiling ,loose between layer and layer, it can spread to the whole roll if it is serious.

10, bird's nest: at the end surface of aluminum coil has local "V" type defect.

Because of so many defects of non qualified aluminum coil product,people has to pay more attention to selecting, if you want a supplier who do not have all these problems, Haomei is your best choice, for we have strict inspect on the quality and producing process,all these problems can be avoid before the aluminum coils are produced. We can promise that all the product from our factory are all with international standard.

Reprinted from: https://www.aluminium-hm.com/new/aluminum-coil-quality.html

评论

发表评论