Usage of aluminum embossed sheet in wet environment

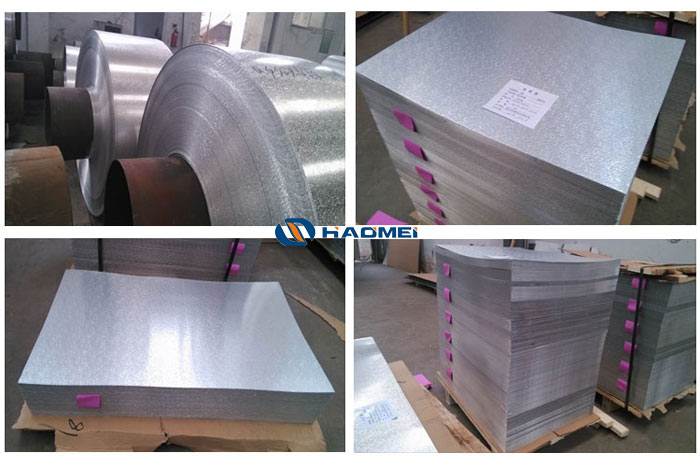

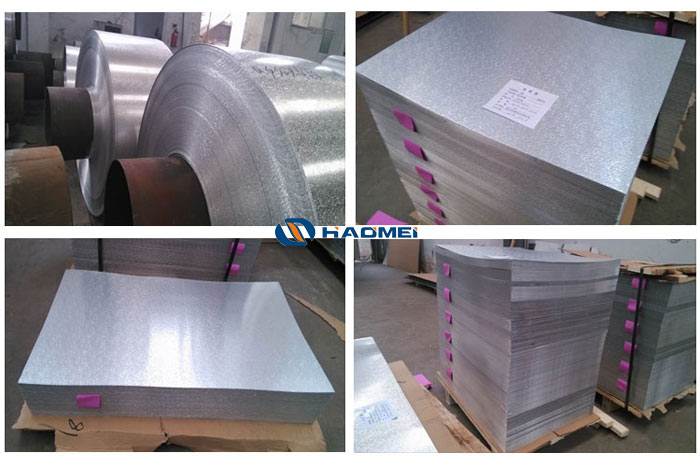

As the performance of aluminum embossed sheet is superior, the range of applications is quite wide, and in the wet environment, the application effect is also outstanding. Today, we are going to talk about the specific application of aluminum embossed sheet in the wet environment. While refers to the wet environment, we have to mention the refrigerator and fridge, used for cooling is the typical usage in wet environment.

In terms of the cooling rate, according to the principle of physics, the thermal conductivity of the aluminum embossed sheet is 237W/ mK, the greater the thermal conductivity coefficient, the better the thermal conductivity, in the same conditions, the faster the cooling rate, the better the cooling effect. In terms of the material, the cost of the aluminum embossed sheet is higher, the good refrigerator choose aluminum embossed evaporator, because the cooling effect is the best. In terms of solder joints and corrosion resistance, high-performance refrigerator cooling tube is wrapped by aluminum embossed sheet on the surface of the evaporator, there is no solder joints, the refrigerant will never leak, it is more safe and healthy! In terms of load-bearing capacity, the refrigerator freezer drawer contact with aluminum embossed sheet fully, the cooling area is bigger, cooling uniform, due to the uniform force, the load capacity of aluminum embossed sheet evaporator can be up to 30 kg. Take all these aspects into consideration, aluminum embossed sheet is really a good choice of cooling in wet environment.

In terms of the cooling rate, according to the principle of physics, the thermal conductivity of the aluminum embossed sheet is 237W/ mK, the greater the thermal conductivity coefficient, the better the thermal conductivity, in the same conditions, the faster the cooling rate, the better the cooling effect. In terms of the material, the cost of the aluminum embossed sheet is higher, the good refrigerator choose aluminum embossed evaporator, because the cooling effect is the best. In terms of solder joints and corrosion resistance, high-performance refrigerator cooling tube is wrapped by aluminum embossed sheet on the surface of the evaporator, there is no solder joints, the refrigerant will never leak, it is more safe and healthy! In terms of load-bearing capacity, the refrigerator freezer drawer contact with aluminum embossed sheet fully, the cooling area is bigger, cooling uniform, due to the uniform force, the load capacity of aluminum embossed sheet evaporator can be up to 30 kg. Take all these aspects into consideration, aluminum embossed sheet is really a good choice of cooling in wet environment.

Reprinted from: https://www.aluminium-hm.com/new/aluminum-embossed-sheet.html

In terms of the cooling rate, according to the principle of physics, the thermal conductivity of the aluminum embossed sheet is 237W/ mK, the greater the thermal conductivity coefficient, the better the thermal conductivity, in the same conditions, the faster the cooling rate, the better the cooling effect. In terms of the material, the cost of the aluminum embossed sheet is higher, the good refrigerator choose aluminum embossed evaporator, because the cooling effect is the best. In terms of solder joints and corrosion resistance, high-performance refrigerator cooling tube is wrapped by aluminum embossed sheet on the surface of the evaporator, there is no solder joints, the refrigerant will never leak, it is more safe and healthy! In terms of load-bearing capacity, the refrigerator freezer drawer contact with aluminum embossed sheet fully, the cooling area is bigger, cooling uniform, due to the uniform force, the load capacity of aluminum embossed sheet evaporator can be up to 30 kg. Take all these aspects into consideration, aluminum embossed sheet is really a good choice of cooling in wet environment.

In terms of the cooling rate, according to the principle of physics, the thermal conductivity of the aluminum embossed sheet is 237W/ mK, the greater the thermal conductivity coefficient, the better the thermal conductivity, in the same conditions, the faster the cooling rate, the better the cooling effect. In terms of the material, the cost of the aluminum embossed sheet is higher, the good refrigerator choose aluminum embossed evaporator, because the cooling effect is the best. In terms of solder joints and corrosion resistance, high-performance refrigerator cooling tube is wrapped by aluminum embossed sheet on the surface of the evaporator, there is no solder joints, the refrigerant will never leak, it is more safe and healthy! In terms of load-bearing capacity, the refrigerator freezer drawer contact with aluminum embossed sheet fully, the cooling area is bigger, cooling uniform, due to the uniform force, the load capacity of aluminum embossed sheet evaporator can be up to 30 kg. Take all these aspects into consideration, aluminum embossed sheet is really a good choice of cooling in wet environment.Reprinted from: https://www.aluminium-hm.com/new/aluminum-embossed-sheet.html

评论

发表评论